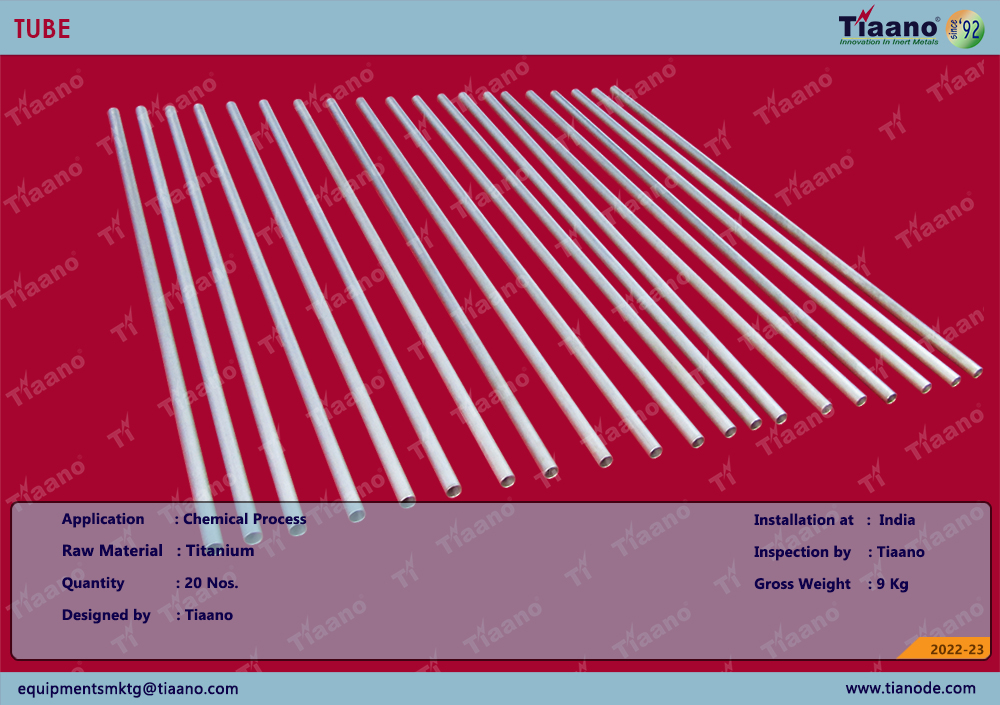

Ti Anode Fabricators Pvt Ltd has an internationally recognized reputation for the manufacture of the Titanium GR.2 Seamless Tube. Titanium Grade 2 Seamless Tube the highest ductility and an excellent resistance from mild to high oxidization.

The Titanium Grade 2 Seamless Pipe is also resistance to seawater, brine and aqua. In applications that require low electrical and themal conductivity , the Titanium Alloy Gr 2 Hollow pipe, which is amongst the four commercially pure grades, is perfectly acceptable. In comparison to aluminum, the Titanium Gr. 2 ERW Pipe is about 60% denser. However, the strength of grade 2 titanium is almost two times that of aluminium.Commercially pure Grade 2 Titanium Pipe can exhibt exceptional resistance to corrosion in highly oxidizing as well as midly reducing service.

Titanium Grade 2 Pipe Specification

|

Size

|

½” to 6” NB Sch 10s, 40s, & 80s, 160s

|

|

Wall Thickness

|

0.1 - 60 mm

|

|

SS Seamless Pipe Length

|

Single Random Length 5to7 mtr

|

|

Double Random Length 10-12 mtr

|

|

Seamless SS Pipe Surface Finish

|

Cold Finish, Bright, Polished, Annealing, Pickling, or as per client requirements

|

|

Standard

|

JIS, AISI, ASME, ASTM, AMS, GB, DIN, EN, GOST

|

|

Manufacturing types

|

Seamless, Welded, ERW, EFW

|

|

Manufacturing Shapes

|

Round, Square, Rectangle, Box Section

|

|

Manufacturing Technology

|

Hot / Cold Formed

|

|

Other Grades

|

SS 446

|

|

Inspection, Test Reports

|

EN 10204 3.1, Mill Test Certificates, PMI Test Reports, Chemical Reports, Mechanical Reports, NABL Approved Lab Reports, Visual Inspection Reports, Destructive and Non Destructive Test Reports, Third Party Inspection

|

|

Technique

|

Cold Rolled Hot Rolled

|

Our sincere team of professionals and employees are always making an extensive effort to make high range of qualitative products which can be completely satisfy the expectations of our reliable consumers. You can avail this range of Clamps at a very reasonable price and with customer customization. We are proficiency in ethical to the equipment demands in diverse industries including Power, Oil & Gas, and Chemical, Water & Waste Water Treatment, Food, Pharma and others.

Enquiry

For any inquiry in regards to Titanium GR.2 Seamless Tube please contact us on +91 8438164458 or email us on equipmentsmktg@tiaano.com.

80842118-fd63-4d2f-b2ae-4f127007b02f|0|.0|27604f05-86ad-47ef-9e05-950bb762570c

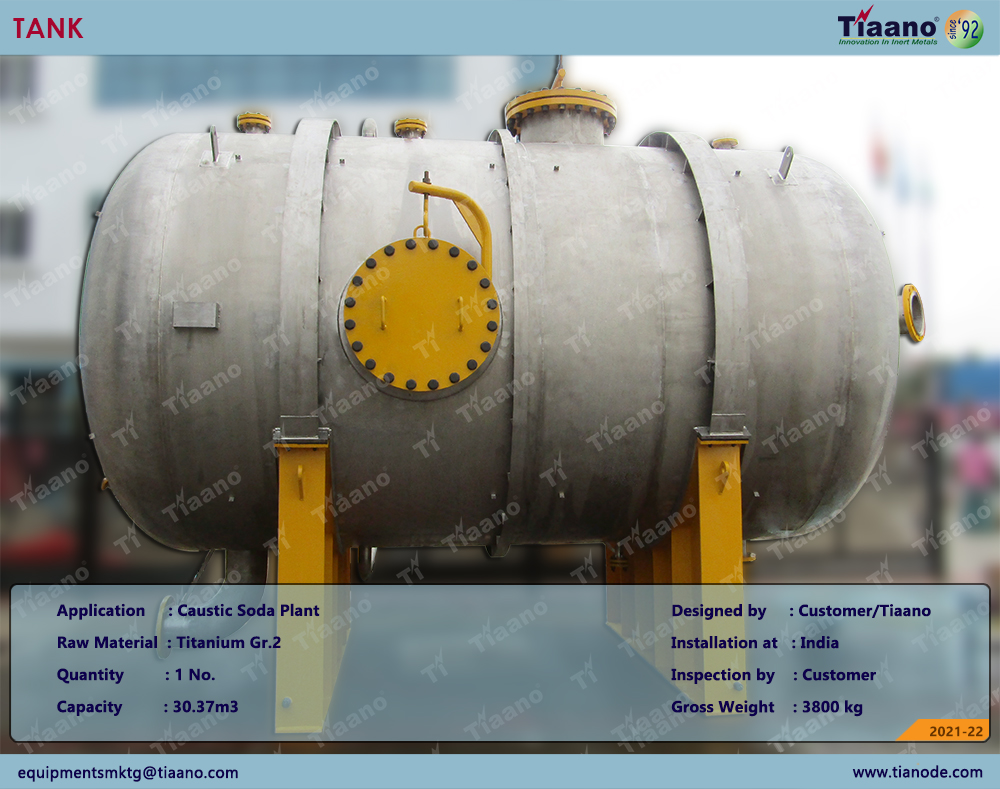

Ti Anode Fabricators Pvt Ltd has an internationally recognized reputation for the manufacture of the Depleted Brine Tank (Titanium Grade 2). It avoids high corrosion resistance. Widely used by mineral water plant and chemical processing plant, Tiaano ‘S engineers provide expert services in the manufacturing of superior quality Depleted Brine Tanks. They can be custom-designed to suit a range of industry use cases.

Industrial Titanium Applications:

Titanium has found in many industrial applications where corrosion resistance is required. Here are some of the common applications of Titanium in corrosion-resistant service:

- Chlorine Chemicals

- Hydrochloric Acid

- Phosphoric Acid

- Sea Water

- Sulfuric Acid

- Nitric Acid

Titanium Fabrications

Tiaano regularly fabricates the following types of Titanium custom process equipment:

- Pre-Engineered OEM Designed Custom Parts / Systems made with Titanium

- Titanium Columns Sections

- Titanium Reactors

- Titanium Pressure Vessels

- Titanium Piping Systems

- Titanium Pipe

- Titanium Sparger

- Titanium Fasteners

- Titanium Agitator

Final selection of material must be based on actual evaluation of the metal in the corrosive medium under study and is the responsibility of the end user. Temperature and concentration play an important factor in corrosion resistance.

Enquiry

For any inquiry in regards to Depleted Brine Tank (Titanium Grade 2) please contact us on +91 8438164458 or email us on equipmentsmktg@tiaano.com.

07eb24f6-1444-42e5-be51-12edcc83a3c4|0|.0|27604f05-86ad-47ef-9e05-950bb762570c